Commercial & Industrial Reverse Osmosis (RO) Systems

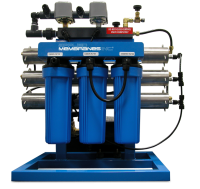

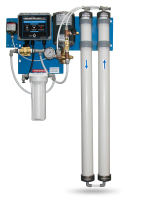

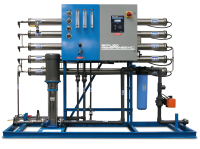

Applied Membranes manufactures Reverse Osmosis Systems (RO Systems) ranging from 24 gallons to millions of gallons per day, treating municipal, well, surface and sea water.

What is Reverse Osmosis?

Reverse Osmosis is a water purification process in which feed water is processed through a membrane. This membrane stops contaminated water, cleaning solutions and undissolved materials from passing through. The clean water is sent along to the point of use and the contaminants are discharged to a drain. The process, combined with pre-filtration, is able to remove 90 to 99.99% of the dissolved impurities that reside in your water.

- Learn More: What is Reverse Osmosis? (Technical Article)

Types of Reverse Osmosis Water Systems

We offer both residential and commercial Reverse Osmosis Systems to fit all of your water treatment needs. Please choose from your application and flow range below to view our Reverse Osmosis Systems in your size.

Request A Quote »

Contact us

for a quote or for any additional information

or call us at 1.800.321.9321