Ultrafiltration UF Systems with Hollow-Fiber UF Membranes

Applied Membranes, Inc. Ultrafiltration (UF) membrane treatment systems are designed to produce clean, purified water from various sources waters, including rivers, lakes, industrial ponds, secondary effluent, well water, and seawater. UF filtrate is used for drinking water, utility water, reclaimed water, food and beverage production, and pretreated source water for RO desalination systems.

Request A Quote »Benefits

Benefits of Hollow Fiber Ultrafiltration (HF UF) Water Treatment Systems

|

Touch Screen P&ID Screen for Inside-Out UF System Shown |

Details

Ultrafiltration (UF) Systems come complete and are skid mounted. These systems are tested before shipment.

|

Standard Equipment

|

|

Ordering Information

|

Inside-Out Model No. |

Outside-In Model No. |

System Capacity |

Membrane Elements |

Line Sizes |

System Dimensions |

Approx. Shipping Weight |

||||||

|

GPM |

GPD |

m³/hr |

Inlet |

Filtrate |

Back- |

Length |

Depth |

Height |

||||

|

HF60-1I |

HF60-1IE |

10 |

14,400 |

2.3 |

1 |

1.5 |

1.5 |

1.5 |

60/152 |

30/76 |

76/193 |

1,000/454 |

|

HF60-4I |

HF60-4IE |

40 |

57,600 |

9.0 |

4 |

4 |

4 |

4 |

80/203 |

30/76 |

76/193 |

1,500/680 |

|

HF60-10I |

HF60-10E |

100 |

144,000 |

22.7 |

10 |

4 |

4 |

4 |

110/279 |

50/76 |

114/290 |

3,000/1,360 |

|

HF60-14I |

HF60-14E |

140 |

201,600 |

31.8 |

14 |

6 |

6 |

6 |

140/356 |

50/76 |

114/290 |

4,200/1,905 |

|

HF60-18I |

HF60-18E |

180 |

259,200 |

40.9 |

18 |

6 |

6 |

6 |

180/457 |

50/76 |

114/290 |

5,500/2,495 |

|

HF60-22I |

HF60-22E |

220 |

316,800 |

50.0 |

22 |

6 |

6 |

6 |

220/559 |

50/76 |

114/290 |

6,300/2,858 |

Notes

- All dimensions and weights are approximate.

- Based on 77 deg. F (25 deg. C.) operating temperature + or – 10 Deg. F (please advise if temperature is

out of this range) - Operating maximums: 75 PSI applied pressure; 20 PSI transmembrane pressure; 300 NTU of

instantaneous turbidity; 200 PPM chlorine @ 200,000 PPM hours (< 50 NTU, typical) - Capacity basis: 24 hour

Voltage/Ordering InformationPlease add our voltage codes to the end of the model number when ordering. Example: HF60-22E-236 = 220/230v / 3 ph / 60 hz Voltage Codes:

Single Phase Not Available |

Features

Features of Hollow Fiber UF Water Treatment Systems

Applied Membranes' Ultrafiltration UF Systems are available in either Outside-In or Inside-Out configurations.

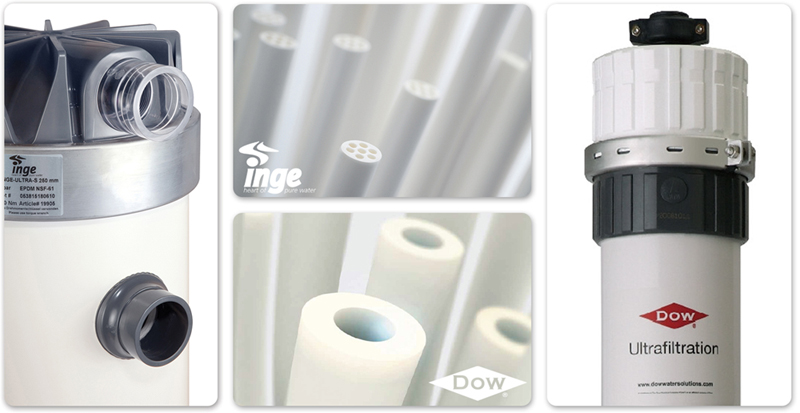

Outside-In configuration UF Systems use DOW UF Low fouling Hydrophilic Polyvinylidenefluoride (H-PVDF) Hollow Fiber Ultrafiltration Membranes and is recommended for applications with feed water higher than 150 ppm total suspended solids. Click here for DOW UF Membrane Specifications

Inside-Out configuration UF Systems use Inge dizzer® XL Low fouling Hydrophilic MPES Hollow Fiber Ultrafiltration Membranes. Dizzer XL UF Membranes are provided with Multibore® technology for superior membrane integrity (robust membrane). Click here for Hydranautics UF Membrane Specifications

Applied Membrane's Ultrafiltration Systems use inge Hollow Fiber Ultrafiltration Modules.

Applied Membrane's Ultrafiltration Systems use inge Hollow Fiber Ultrafiltration Modules.

|

About inge Hollow Fiber UF Modules Multibore® membrane - The patented Multibore® membrane technology combines seven individual capillaries in a highly robust fiber – an arrangement that significantly increases the membrane's stability and eliminates the risk of fiber breakage. The membrane provides a secure barrier against suspended solids, bacteria, viruses and other microorganisms and supplies a consistently high level of filtrate quality, even in cases where the composition of the original water varies. dizzer® module - Compact and high-capacity ultrafiltration. Thanks to an optimum hydrodynamic design combined with the top-notch treatment efficiency of the Multibore® membrane, the dizzer® module sets new standards in ultrafiltration technology. T-Rack® - Space-saving and efficiency-boosting: the T-Rack® is an integrated, ultracompact rack system that is equipped with dizzer® XL ultrafiltration modules. The inlet and outlet lines are already integrated in the end caps – a design feature that makes the system's footprint considerably smaller.

|

Systems using Hydranautics HYDRAcap® Hollow Fiber Ultrafiltration Modules and DOW UF / Omexcell Ultrafiltration Modules are also Available

|

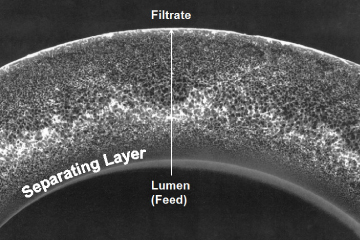

About Hydranautics HYDRAcap Hollow Fiber UF Modules: HYDRAcap products contain capillary fiber membrane made from a hydrophilic polyether sulfone, with a nominal molecular weight cutoff of 150,000 Daltons. Feed water enters the center (lumen) of the fibers and permeates through the membrane radially outward, producing a filtrate turbidity typically less than 0.07 NTU. A magnified, cross sectional view of the membrane is shown in figure 1 to the right. The HYDRAcap modules in these systems are operated in the directional flow ("dead-end") method, where all of the feed water is converted to filtrate. The Ultrafiltration modules are regularly backwashed to restore permeability, which declines as solids build up on the membrane. The pH tolerance (1.5 - 13.0) of the membrane allows for the addition of chemicals for cleaning and chemically enhanced backwashing. |

About DOW UF Modules:

The DOW™ Ultrafiltration module utilizes a double-walled hollow fiber (capillary) PVDF membrane which has a very small nominal pore diameter for PVDF material that allows for the removal of all particulate matter, bacteria and most viruses and colloids. Despite the small pore diameter, the membrane has a very high porosity resulting in a flux similar to that of micro-filtration (MF) and can effectively replace MF in most cases.

Systems designed with DOW™ Ultrafiltration use an outside-in flow configuration which allows for less plugging, higher solids loading, higher flow area and easy cleaning. The primary flow design is dead-end filtration but the module can be operated using a concentrate bleed. Dead-end filtration uses less energy and has a lower operating pressure than the concentrate bleed, therefore reducing operating costs.

Typically, DOW™ Ultrafiltration is operated at a constant permeate flow. The transmembrane pressure (TMP) will naturally increase over time and the module can be cleaned periodically by back flushing and air scouring to remove the fouling layer. Disinfectants and other cleaning agents can be used to fully remove and prevent performance loss due to biological growth as well as other foulants.

About DOW OMEXELL Ultrafiltration Membranes:

The OMEXELL™ ultrafiltration modules are made from high strength, hollow fiber membranes that have excellent features and benefits:

- 0.03 μ nominal pore diameter for removal of bacteria, viruses, and particulates including colloids to protect downstream processes such as RO

- PVDF polymeric hollow fibers for high strength and chemical resistance allows long membrane life

- Hydrophilic PVDF fibers for easy cleaning and wettability that help maintain long term performance

- Outside In flow configuration for high tolerance to feed solids that help reduce the need for pretreatment processes

- U-PVC housing, helping to eliminate the need for costly pressure vessels

Applications

Applications for Hollow Fiber Ultrafiltration (HF UF) Water Treatment Systems

- Purification of surface water, groundwater and spring water to make drinking water and process water

- Treatment of waste water

- Pretreatment in sea water desalination plants in combination with reverse osmosis or thermal treatment

- Water for industrial use to close water cycles and a wide variety of other applications

Contact us

for a quote or for any additional information

or call us at 1.800.321.9321