AMI water treatment solutions for microelectronics and semiconductor rinse water remove contaminants, minerals, microorganisms and trace chemicals to produce ultrapure water (UPW) that meets the stringent purity level requirements required in manufacturing.

Semiconductor chip manufacturing processes and fabrication plants require ultrapure water at nearly every step. These fabs use millions of gallons of water daily for rinsing, cleaning and processing wafers. Proper water treatment design and water reuse helps manage consumption and drive more sustainable operations.

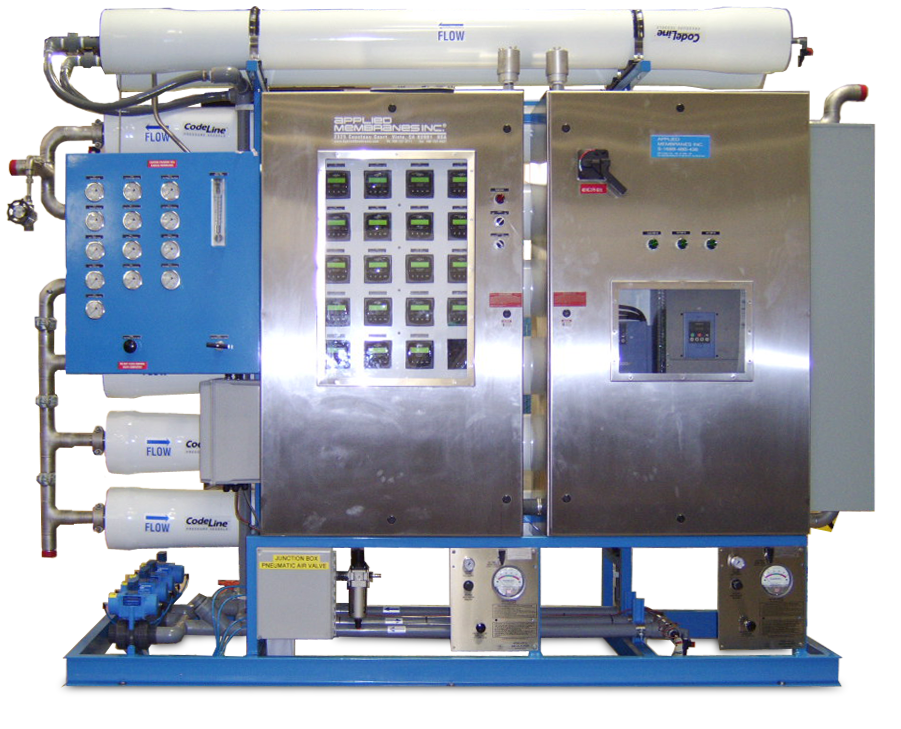

Treating raw water to the purity levels required in semiconductor manufacturing demands a robust sequence of advanced processes and water treatment technologies for removing contaminants, minerals, microorganisms, and trace organic and nonorganic chemicals, including other nanoscale particles. AMI systems for semiconductor rinse water are designed to produce ultrapure water (UPW) to be used in cleaning and etching processes and to wash and rinse semiconductor parts throughout the manufacturing cycle.

Brine water from industrial processes can be treated and reused instead of being discharged, reducing water waste. This brine may contain valuable minerals and metals which can be further concentrated and recovered.

Treating raw water to the purity levels required in semiconductor manufacturing demands a robust sequence of advanced processes and water treatment technologies for removing contaminants, minerals, microorganisms, and trace organic and nonorganic chemicals, including other nanoscale particles. AMI systems for semiconductor rinse water are designed to produce ultrapure water (UPW) to be used in cleaning and etching processes and to wash and rinse semiconductor parts throughout the manufacturing cycle.

Brine water from industrial processes can be treated and reused instead of being discharged, reducing water waste. This brine may contain valuable minerals and metals which can be further concentrated and recovered.

AMI has many ultrapure water treatment and high recovery systems operating in the microelectronics and semiconductor industry worldwide. Our list of successful installations includes Hua Yue Microelectronics and many more.