found for ""

1.2 MGD Ultrafiltration Water Treatment for Food Processing Plant

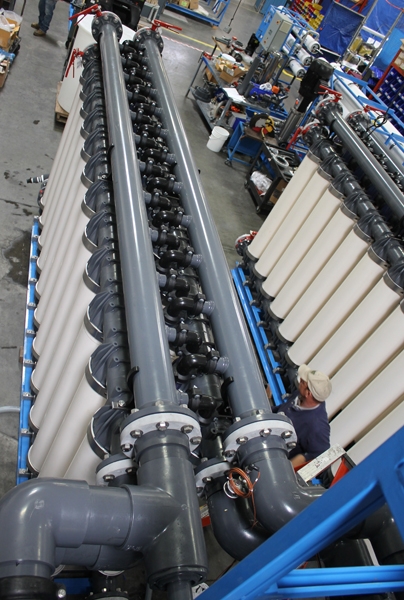

A food processing plant in Peru was faced with natural ground water contaminated with high turbidity and arsenic, making it unsuitable for use in food processing. AMI’s custom engineered solution incorporates ultrafiltration membranes with pretreatment by coagulant and depth filtration, as well as chlorination of the filtrate to produce water meeting the customer’s high quality standards for use in food product processing. The complete installation supplies up to 880 gallons per minute of treated water to meet the company's production demands.

The hollow fiber ultrafiltration membrane water treatment system is provided in two treatment trains, each rated to treat 440 gpm of well water. The system is AMI PLC automated using a central control enclosure and touchscreen HMI operator interface. Chemical enhanced automatic cleaning prolongs membrane life to provide lower operating costs, less maintenance and reduced down time. The membrane system features BAS-Inge hollow fiber UF modules, 100 Micron prefiltration, automated backwash, filtrate flush, and chemically enhanced cleaning. Chemical skids provide coagulant, disinfection, and post chlorination.

Request A Quote »

- Flow Rate

- 880 GPM

- 3,331 LPM

- 4,800 M3/Day

- 2014

- Peru

- Application

- Food Processing

- Ultrafiltration (UF)

- Chemical Injection

- Depth Filtration

- Touch Screen PLC Programming

- Cleaning: CEB automated cleaning with CIP enhanced cleaning system

- Flushing system: Automated backwash with UF filtrate

- Chemical skids: Pretreatment coagulant and disinfection, post chlorination

- Equipment skid mounted on powder-coated frames