Water is essential for the power generation sector including refining, steam generation and cooling processes. AMI water treatment solutions provide high quality water for boiler feed and cooling towers, prevent scaling and corrosion and extend equipment lifespan. In power plants, high purity water is essential for driving turbines and generating electricity efficiently. Our advanced water treatment systems remove impurities and produce high quality water, optimizing turbine performance, extending equipment lifespan, and improving overall plant efficiency. We offer reliable water treatment solutions for the power generation sector with performance you can count on. AMI advanced water treatment systems optimize water reuse and minimize water footprint. We provide robust treatment solutions for challenging feedwater conditions in upstream and downstream operations.

Power Generation

Benefits

- Extended equipment lifespan

- Consistent water quality

- Improved uptime and operational efficiency

- Reliable and scalable solutions

- Compliance with standards

Product Lines: Power Generation

Commercial & Industrial RO

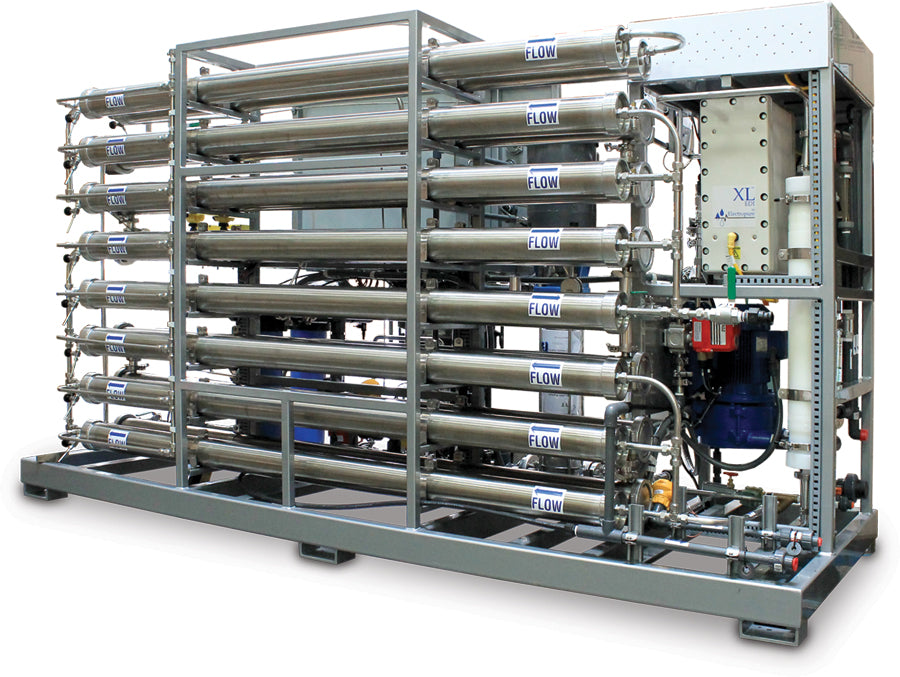

AMI manufactures Reverse Osmosis Systems (RO Systems) ranging from 24 gallons to millions GPD treating municipal, well, surface and sea water. Learn MoreCustom Systems

Custom engineered water treatment systems for dialysis, boiler feed water, dye recovery, ground water remediation, mobile water purification and more. Learn MoreHollow Fiber UF

UF Systems produce purified water from various sources waters, including rivers, lakes, industrial ponds, secondary effluent, well water and seawater. Learn MoreMedia Filtration

Water Softeners, Carbon Filters, Multi-Media Filters, and Other Media Filters with Fleck Control Valves Learn MorePilot Plants

For testing applications using Reverse Osmosis, Ultrafiltration, Nanofiltration, or Microfiltration technology and testing applications such as USP, dairy, and more. Learn MoreUltra-High Recovery (UHR)

Ultra-High Recovery Near Zero Liquid Discharge (ZLD) Reverse Osmosis systems operate at 90 to 98% Recovery. AMC series can use NF membranes to target specific ion rejection, including TOC & COD, for optimized performance. Learn MoreRelated Articles:Power Generation

|

Boiler Feed Water RO System For San Diego Gas & Electric | 1990 |

|

Zero Discharge Case Study |